Changing dropouts is one of the most complicated frame modifications to perform, and requests for those retrofits are becoming increasingly common as so many vintage frames built with durable materials like steel and titanium outlast the axle and brake standards of their day.

The complication is largely due to the sheer variety of dropouts that are in circulation.

Unlike head tubes, bottom bracket shells, main tubes, and other frame components that have traditionally been widely standardized and used more or less interchangeably on frames across all disciplines (the stalwart BSA English bottom bracket can be found on the vast majority of road, mountain, track, tandem, and even recumbent bikes built over the last half century), chain-stays and dropouts are rarely common across different product categories. Instead they have been made in a plethora of shapes and sizes, often designed for a specific functionality or axle/brake/spacing standard, and sometimes with proprietary dimensions or fitments.

The lengths, angles, and shapes of a bike frame’s rear triangle ensure that the rear axle is placed in a precise location; changing that location by even a few millimeters can noticeably impact the handling of the bicycle, not to mention creating the potential for interference issues with brake calipers, cassette lock rings, and other component parts that are subsequently designed to reference the rear axle location.

It is easy enough to consider a number of dropout styles when designing a frame, before the tubes are cut. But when it comes to retrofits the details of the original rear triangle design often preclude simply cutting one dropout out and welding another one in. This is especially the case when the retrofit is intended to change the application/format of the frame: from a vertical road dropout to a horizontal track dropout; from a fixed non-disc quick release dropout to an adjustable thru-axle disc brake dropout, et cetera.

Different styles of dropouts -- especially those designed decades apart for different axle, brake, and spacing standards -- rarely have similar shapes, lengths, or angles of attachment for stays. Moreover, even across a size run within a single frame model/design there are often dramatic differences in the angle at which seat-stays and dropouts intersect; with all other design variables kept neutral a 49cm frame’s seat stay will attach to the dropout at a much more acute angle than a 61cm frame of the same model.

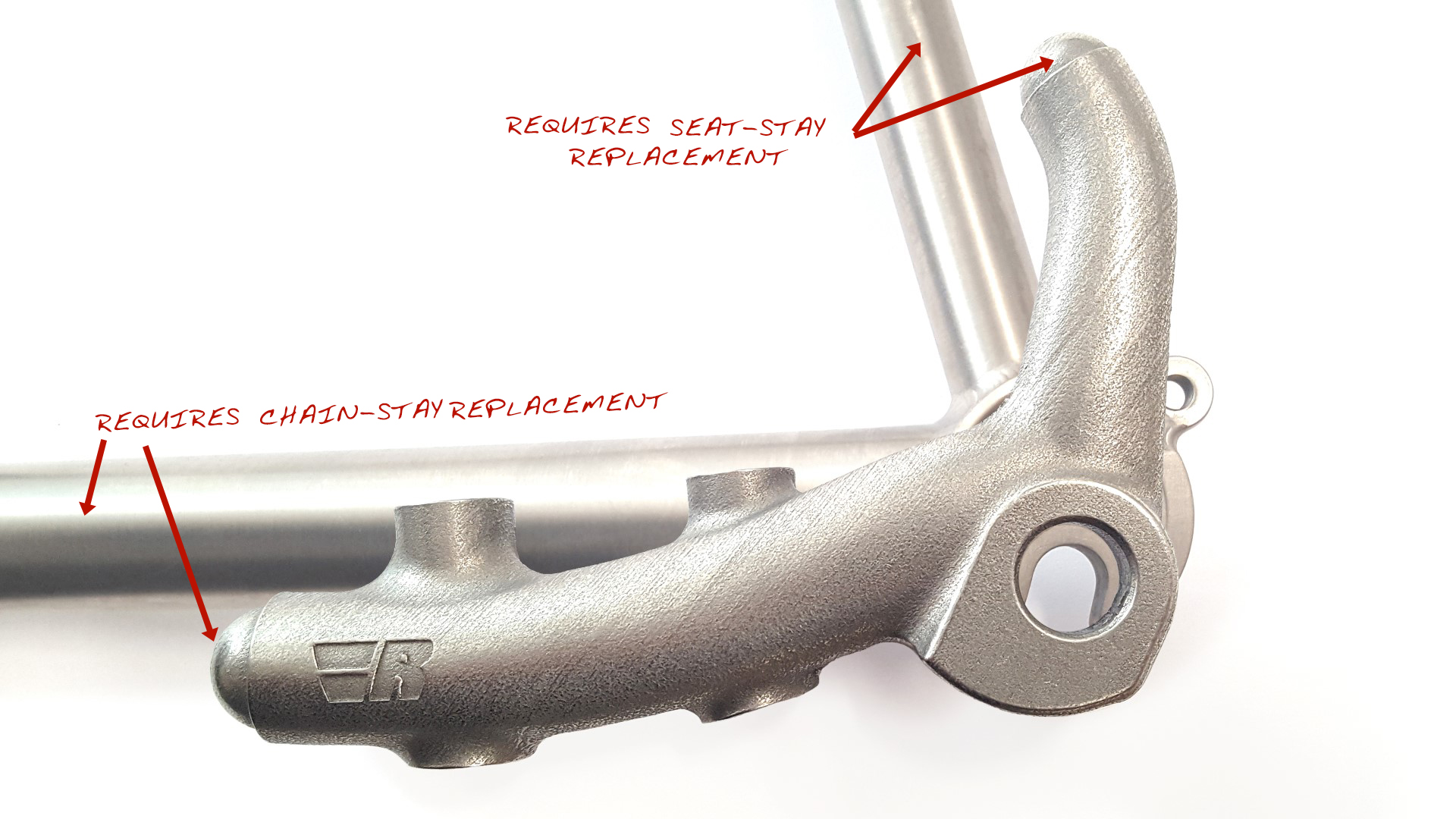

Ultimately this means that the replacement of entire chain-stays and/or seat-stays are often required to keep the rear axle in the same location.

For an example, see the images below, showing the complications with one of the more common requests: converting a traditional 130QR rim brake frame to a 142x12 disc brake frame with the Reynolds R3D flat mount dropout. The impediments to an easy conversion are numerous and obvious.

That said, Yes! it is possible to retrofit most frames with dropouts of almost any style. It will likely not be simple or easy, and it may require custom dropout fabrication, chain-stay and/or seat-stay replacement to work, but it can be done.

It is also worth noting that some dropout retrofits, especially when converting a non-disc brake frame to disc, offer the potential for cost savings when updating to modular setups like Rocker Dropouts. These systems use a frame fitment that uses dropout inserts with an integrated disc caliper mount, eliminating the need for a separate disc brake conversion.

To be fair, sometimes serendipity provides for a replacement dropout that mates well enough with an existing rear triangle that it is possible to do a straightforward cut-and-replace. This best case scenario is rare and still involves several hours of shop time and new dropouts, but is ultimately much more affordable than a more complicated retrofit that requires replacing stays.

For a retrofit quote please reach out with information on your bike, along with photos, as well as your end objective and budget. We are here to help!